Functional Fungi™ uses a mushroom cultivation process that was developed 20 years ago in Japan. We are one of the early pioneers using solid-state fermentation for mycelium development.

Grown in the US, we use regenerative farming techniques to ensure consistency and continuity from batch to batch. All lots are tested for species identification, safety and purity.

Our superfoods-based growth process features High Antioxidant (anthocyanins) substrates like Purple Corn in the patented Functional Fungi™ process.

This results in greater nutritive value in our mushrooms versus competitive suppliers that grow on inert, non-nutritive substrates like sawdust.

| Publication number: | 20180000013 |

| Abstract: |

The invention is a method for enhanced growth of mycelium in culture including the key steps of seed blend choice from among corn, rice, quinoa, chia, canihua, cumin and flax seed, germinating the seed blend prior to inoculating the mycelium starter, and conducting the mushroom cultivation with ORP enhanced water and particular transmissions of sound and particularly colored light. Mushrooms grown by such a method not only mature in 13-15 days rather than 21 days, but have an enhanced nutritional and medicinal profile along with absence of unwanted organism contaminants whose unwanted overgrowth occurs during days 16-21 (or days 16-28) of typical mushroom culture.

| Type | : | Application |

| Filed | : | February 17, 2017 |

| Publication date | : | January 4, 2018 |

| Inventor | : | Jordan Seth Rubin |

| Publication number: | 20200187432 |

| Abstract: |

The invention is a method for enhanced growth of mycelium in culture including the key steps of seed blend choice from among corn, rice, quinoa, chia, canihua, cumin and flax seed, germinating the seed blend prior to inoculating the mycelium starter, and conducting the mushroom cultivation with water and particular transmissions of sound and particularly colored light. Mushrooms grown by such a method not only mature in 13-15 days rather than 21 days, but have an enhanced nutritional and medicinal profile along with absence of unwanted organism contaminants whose unwanted overgrowth occurs during days 16-21 (or days 16-28) of typical mushroom culture.

| Type | : | Application |

| Filed | : | February 26, 2020 |

| Publication date | : | June 18, 2020 |

| Inventor | : | Jordan Seth Rubin |

| Publication number: | 20190320596 |

| Abstract: |

The invention is an important innovation in mushroom culture in which not only are mycelia beneficially grown on the novel combination of a grain (or seed) and an herb, in the preferred embodiment of the invention the mycelial mass is grown in a co-fermentation with all of a grain (or seed), an herb and a juice. The resulting mycelial biomass contains dramatically improved medicinal and nutritional constituents compared to mushrooms grown on standard, prior art media.

| Type | : | Application |

| Filed | : | February 1, 2019 |

| Publication date | : | October 24, 2019 |

| Inventor | : | Andrew Hines Miller, Jordan Seth Rubin |

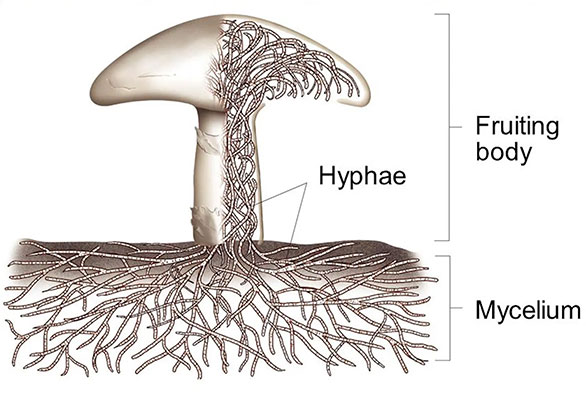

It is fleshy, contains spores, and grows above ground or directly on the surface of its host, like a tree or old log.

The mushroom's fruiting body comprises a stem, cap, and gills, which are what the general populace would eat in a culinary dish, but in nature, it acts primarily as the reproductive component of a fungal system, dispersing spores and inoculating hosts.

Not all mushrooms have a fruiting body.

Mycelium is the main body and feeding membrane of a mushroom. It grows underground or within the host plant.

While it might not look like much, the mycelium acts much like a complex network that can communicate with and adapt to its surrounding environment. Think of it like the roots of the mushrooms.

The mycelium is responsible for taking in nutrients by breaking down decaying matter using various enzymes. These nutrients are absorbed and transferred through hyphae to feed and support not just the fungus itself but whole ecosystems.